In an age where efficiency is paramount, the logistics and supply chain management sectors are witnessing a paradigm shift, driven by one of the most transformative technologies of our time: artificial intelligence (AI). As businesses strive to meet the demands of an increasingly complex market, AI is emerging as a game changer, reshaping how organizations approach inventory management, transportation, and customer service. From predictive analytics that enhance decision-making to automation that streamlines operations, AI is not just a tool; it’s a strategic partner in driving growth and resilience. In this article, we will explore the various ways AI is revolutionizing logistics, the challenges it addresses, and the innovative solutions that are setting the stage for a more efficient and responsive supply chain ecosystem. Join us as we delve into the future of logistics, where intelligence meets innovation.

Table of Contents

- Understanding AIs Impact on Supply Chain Efficiency

- Leveraging Predictive Analytics for Smarter Inventory Management

- Enhancing Last-Mile Delivery Through Machine Learning Solutions

- Implementing AI-Driven Strategies for Risk Mitigation in Logistics

- Insights and Conclusions

Understanding AIs Impact on Supply Chain Efficiency

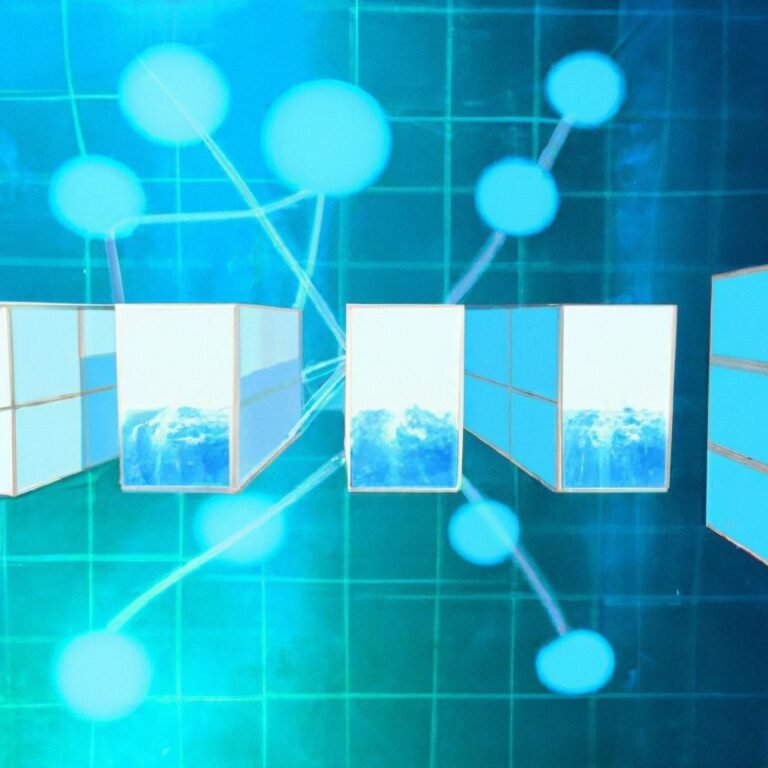

The integration of artificial intelligence into supply chain operations has fundamentally reshaped the way businesses approach logistics and efficiency. AI technologies, such as machine learning and predictive analytics, empower companies to enhance decision-making and optimize processes. By analyzing vast amounts of data, AI can identify patterns and provide forecasts that help manage inventory levels, reduce operational costs, and minimize lead times. This allows organizations to respond swiftly to market fluctuations, ensuring that goods are available when and where they are needed, ultimately leading to increased customer satisfaction.

Moreover, AI facilitates improved visibility across the supply chain, enabling real-time monitoring of goods and resources. This transparency helps in identifying bottlenecks and inefficiencies, which can be addressed proactively. Key benefits include:

- Enhanced Demand Forecasting: AI algorithms can analyze historical sales data and market trends to predict future demand accurately.

- Automated Processes: Robotics process automation (RPA) can handle repetitive tasks, allowing human resources to focus on strategic initiatives.

- Optimized Routing: AI can analyze traffic patterns and delivery schedules to determine the most efficient shipping routes.

The table below highlights some of the key AI technologies currently making waves in supply chain management:

| Technology | Application |

|---|---|

| Machine Learning | Demand forecasting and inventory management |

| Robotics Process Automation (RPA) | Streamlining administrative tasks |

| Natural Language Processing (NLP) | Enhancing customer service interactions |

| Predictive Analytics | Risk management and disruption prediction |

Leveraging Predictive Analytics for Smarter Inventory Management

As businesses seek to optimize their logistics operations, harnessing the power of predictive analytics has emerged as a game changer in inventory management. By analyzing historical sales data, market trends, and even factors like seasonality, companies can forecast demand with remarkable accuracy. This sophisticated approach enables organizations to achieve a delicate balance between supply and demand, minimizing both surplus and stockouts. The key benefits of incorporating predictive analytics into inventory management include:

- Improved Accuracy: Enhanced forecasting reduces guesswork, leading to more reliable inventory levels.

- Cost Reductions: By preventing overstocking, businesses can save on storage costs and reduce waste.

- Enhanced Responsiveness: Real-time data analytics allows for quick adjustments to inventory based on changing market conditions.

Implementing these insights can be facilitated through a combination of advanced technologies. Many organizations are turning to AI-powered tools that not only collect data but also provide actionable insights to streamline the decision-making process. For instance, here’s a simplified comparison of traditional inventory management versus a predictive analytics-driven approach:

| Aspect | Traditional Inventory Management | Predictive Analytics-Driven Management |

|---|---|---|

| Forecasting Method | Historical Sales Only | Multi-variable Analysis |

| Flexibility | Low | High |

| Response Time | Slow | Instantaneous |

| Cost Efficiency | Often High | Optimized |

Enhancing Last-Mile Delivery Through Machine Learning Solutions

In today’s fast-paced world, last-mile delivery has emerged as a critical component of the logistics sector. Machine learning solutions are revolutionizing this segment by optimizing routes, predicting delivery times, and enhancing overall efficiency. By analyzing vast amounts of data in real-time, these technologies help businesses anticipate challenges such as traffic patterns, weather conditions, and customer availability. This leads to improved delivery accuracy and minimized delays, creating a more seamless experience for both companies and consumers alike.

Furthermore, adopting machine learning can facilitate smarter decision-making regarding resource allocation. Companies can leverage data to ascertain the best times for delivery, thereby managing fleet assets more effectively. Key benefits of integrating machine learning into last-mile delivery include:

- Dynamic Routing: Algorithms can update routes on-the-fly based on live traffic data.

- Demand Forecasting: Anticipating peak times helps in resource planning and reducing operational costs.

- Driver Performance Analysis: Evaluating driver behavior can enhance training and overall service quality.

Implementing AI-Driven Strategies for Risk Mitigation in Logistics

In the dynamic landscape of logistics, integrating AI-driven methodologies significantly transforms risk management frameworks. By leveraging advanced algorithms and machine learning models, logistics companies can predict potential disruptions before they materialize. This proactive approach involves analyzing vast datasets to uncover patterns and identify vulnerabilities in supply chains, including supplier reliability and shipment timelines. The use of AI tools enhances decision-making processes, allowing companies to implement real-time adjustments and optimize routes to minimize delays and costs. Additionally, AI enables organizations to build more resilient supply chains by simulating various risk scenarios, thereby facilitating strategic contingency planning.

Moreover, the implementation of AI technologies allows for enhanced visibility across the logistics network. Automated systems, such as AI-powered dashboards, enable stakeholders to monitor performance metrics and swiftly respond to unforeseen challenges. Companies can benefit from the following advantages when incorporating AI in risk mitigation:

- Improved accuracy: AI algorithms analyze data with precision, reducing human error in risk assessments.

- Cost efficiency: Automation decreases operational costs by optimizing resource allocation.

- Scalability: AI systems can easily scale with the growth of the business, ensuring ongoing effectiveness in risk management.

Insights and Conclusions

As we navigate the complexities of modern supply chains, it’s clear that artificial intelligence is more than just a technological trend; it’s a transformative force that is reshaping the logistics landscape. From predictive analytics that anticipate demand to autonomous vehicles that streamline deliveries, AI is enabling companies to operate with unprecedented efficiency and agility.

Embracing these advancements not only enhances operational performance but also fosters a culture of innovation within organizations. As the logistics sector continues to evolve, companies that leverage AI will find themselves better positioned to meet the challenges of tomorrow, delivering enhanced customer satisfaction and sustainable practices.

As we reflect on this journey of transformation, it’s essential for businesses to remain proactive in adopting AI solutions and integrating them into their strategies. The future of supply chain management is not just about technology; it’s about harnessing the power of AI to create smarter, more resilient operations.

Thank you for joining us in exploring the pivotal role of AI in logistics. Keep an eye on this dynamic field, as the innovations that emerge will undoubtedly shape the way we understand and approach supply chain management for years to come. Stay informed, stay ahead, and let’s embrace a future where logistics is powered by intelligence.